From Unloading to Final Packaging

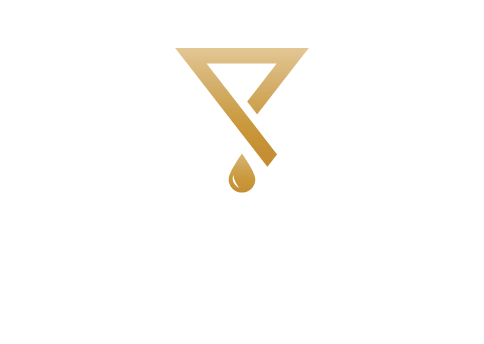

The process begins with the Bin Tipper UNLOADER 800, allowing for safe and efficient bulk unloading. Berries are transferred onto the Sorting Conveyor, where an operator can visually inspect and manually select only the best fruits to move forward in the process.

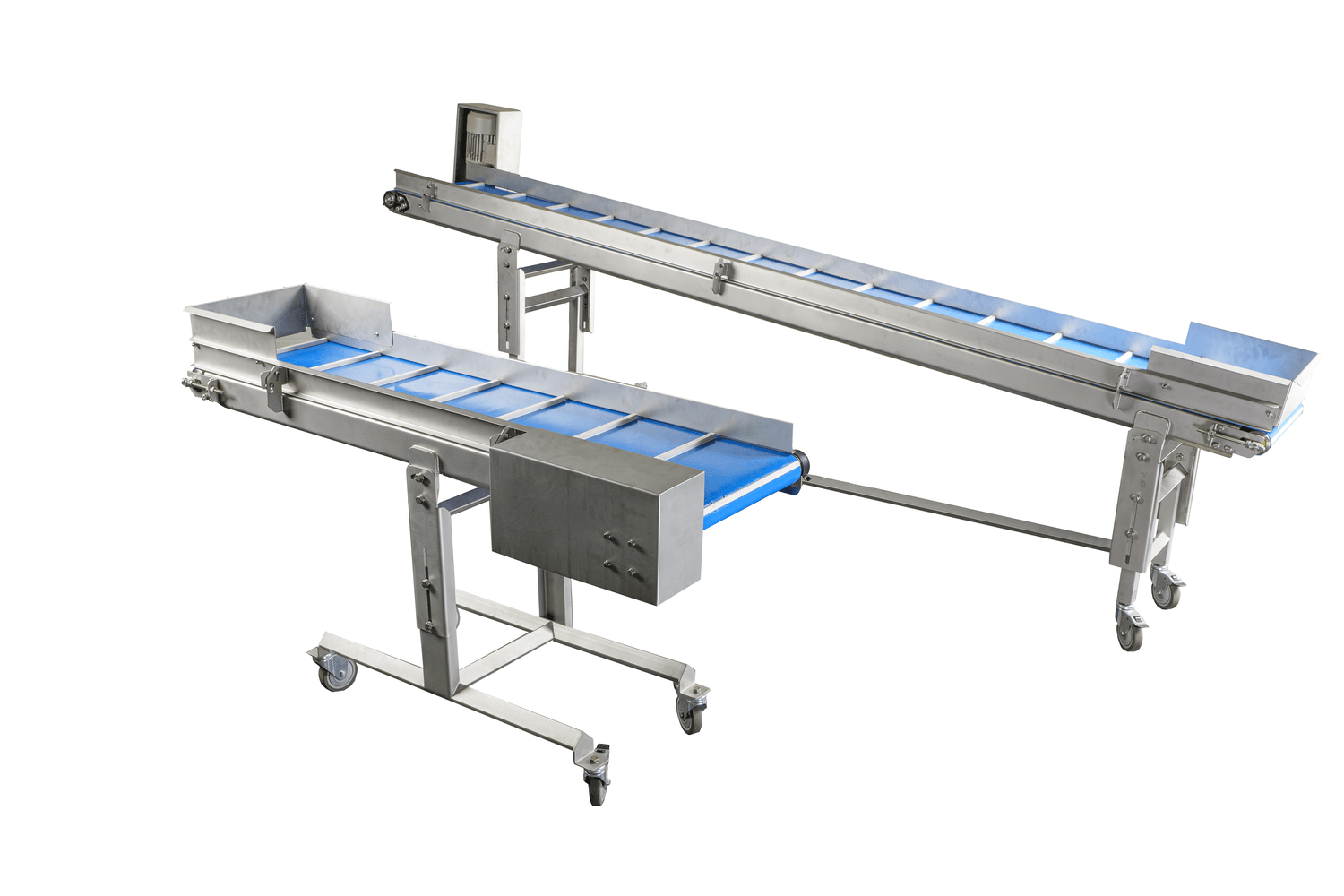

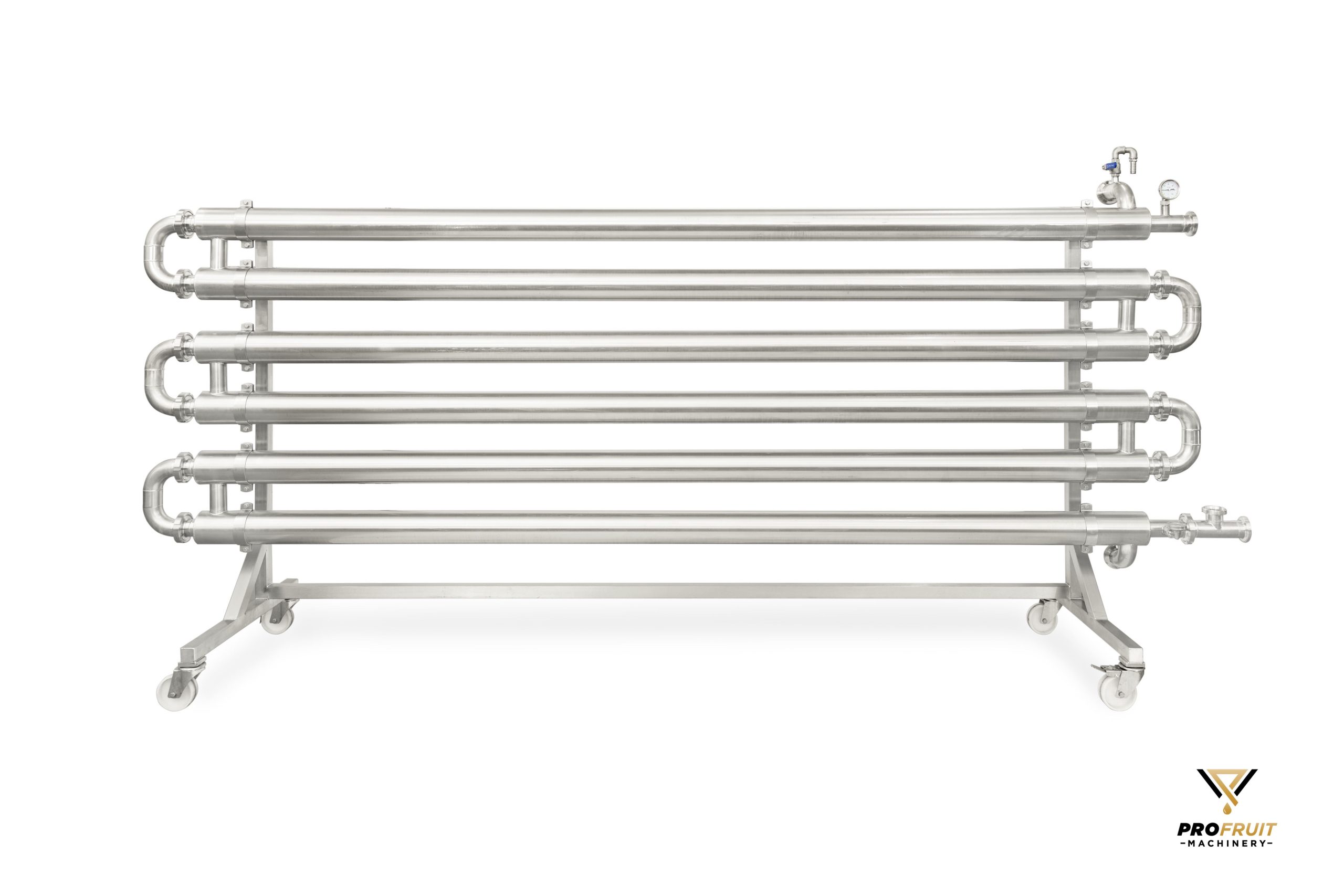

Depending on your process setup, berries are washed and crushed using the Fruit Bubble Washer Elevator Mill AQUAMILL. If prewashed, the process can begin with the Berry and Fruit Crusher, which prepares the fruit for pressing. The resulting mash is transferred by the Monopump for Fruit Mash to the Tube-in-Tube Heat Exchanger, where it is gently heated to the ideal pressing temperature.

Juice is then extracted using the Pneumatic Press for Berries & Other Fruits – a system that applies soft yet effective pressure for maximum yield without compromising quality.

Homogenization, Pasteurization, and Packaging

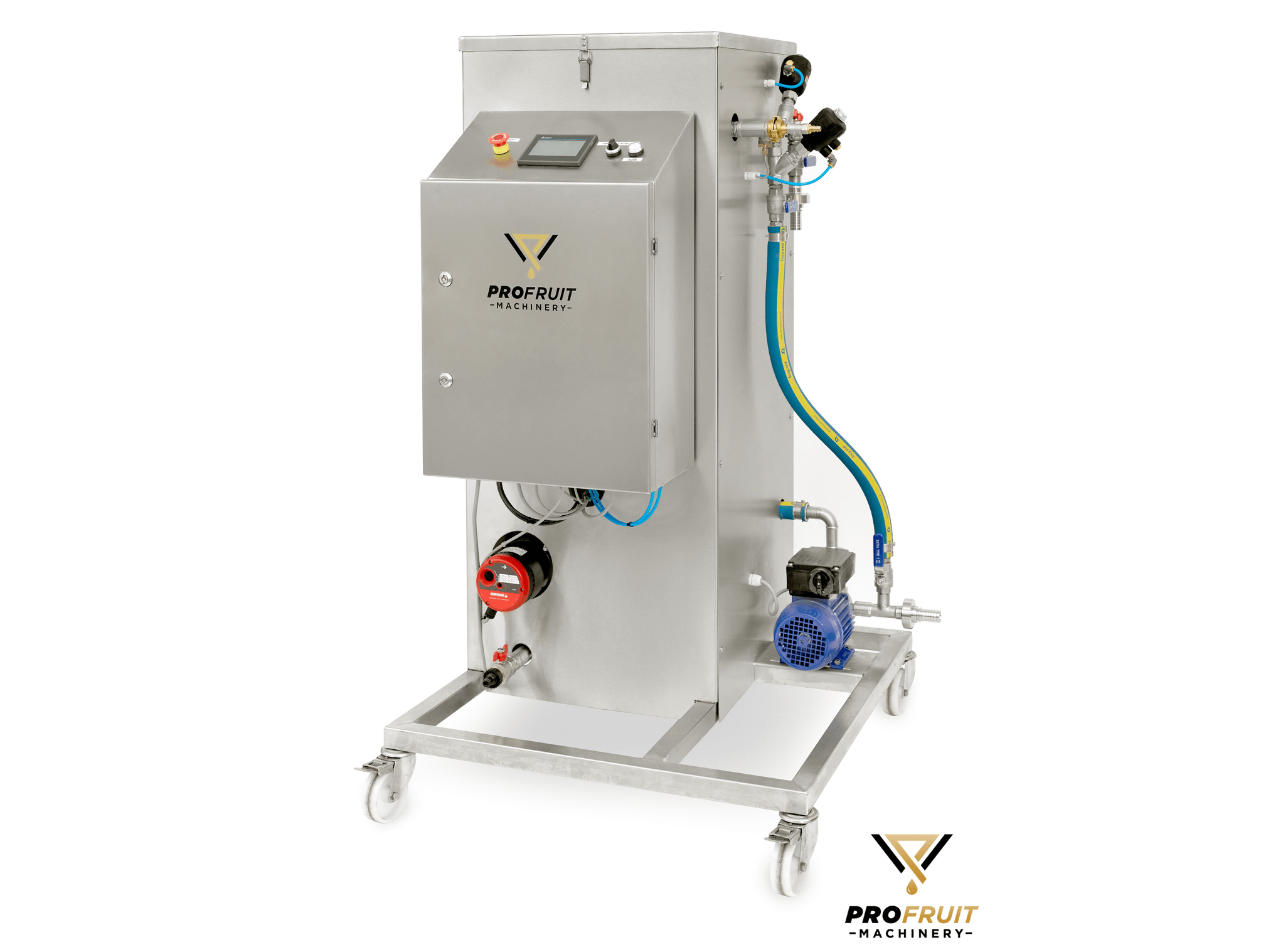

The extracted juice is collected in stainless steel tanks, where it can be stored, blended, or prepared for bottling. To ensure consistency, the juice undergoes treatment in the Juice Homogenizer, and is then pasteurized using either the Diesel/Gas Pasteurizer HEAT or the Electric Pasteurizer ECO HEAT, both of which ensure product safety and long shelf life.

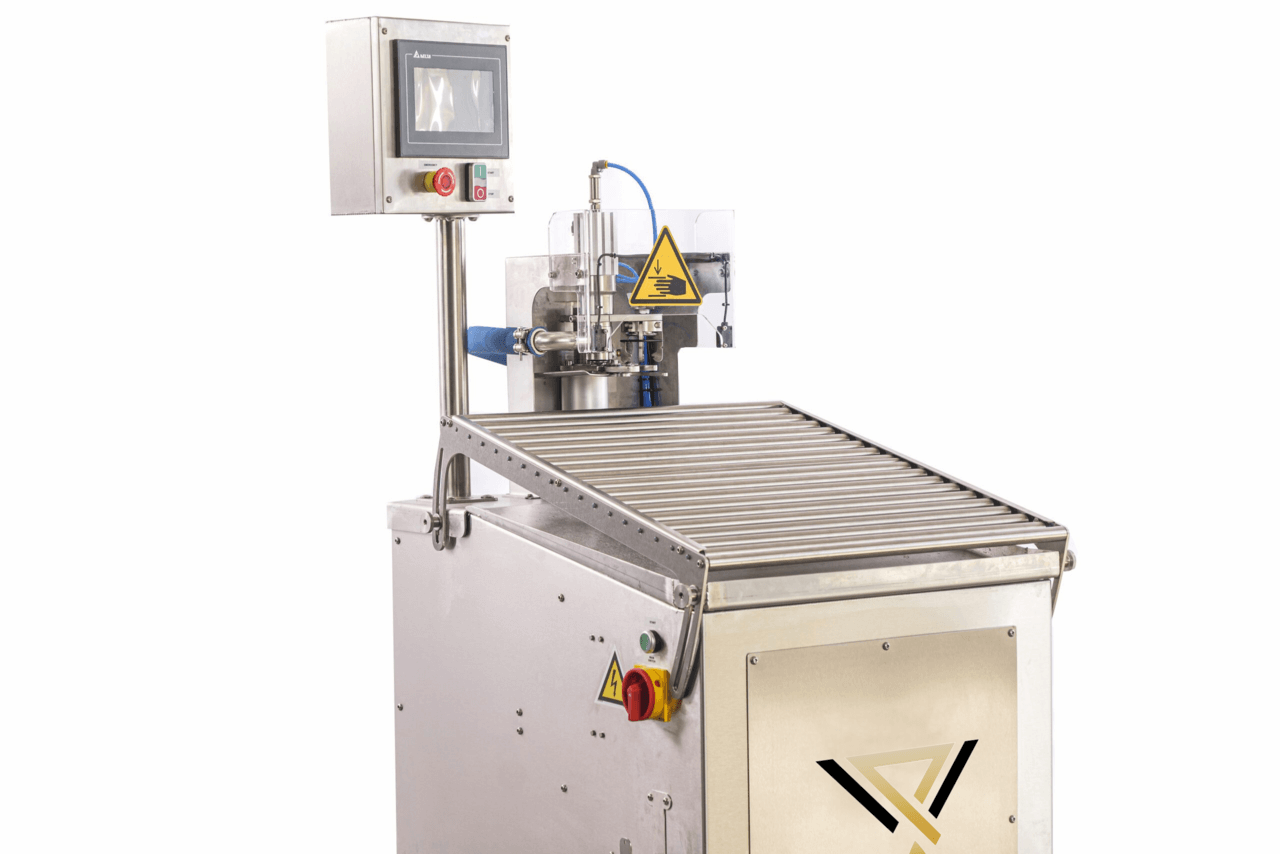

Packaging is completed using the Automatic Bag in Box Filler AUTOFLOW, Manual Bottle Filler GRAVITY or automatic bottling systems, depending on your scale and preference.

Why Choose ProFruit?

- Complete berries juice processing solutions

- Gentle pressing systems for delicate fruits

- Fully integrated fruit processing machine line

- Expertly engineered for efficiency, hygiene, and scalability

With ProFruit’s equipment, you’re investing in reliable, high-yield systems designed to optimize your berry juice production from start to finish.