Automatic Triblock Bottling Line

Complete Triblock Bottling Line – solution for Juice & Beverage Production

Discover PROFRUIT MACHINERY automated bottling line that is designed to take your product from raw liquid to a retail-ready multipack.

Step 1: Product Pasteurization for a Hot-Fill Production Line Equipment

The process begins with raw product that first is processed through a high-efficiency PROFRUIT Juice Pasteurizer. Available in Diesel, Gas, or Electric models, these units use an advanced shell and tube heat exchanger to rapidly bring the liquid to the precise pasteurization temperature. This critical hot-fill process eliminates microbes, extends shelf life, and prepares the sterile, hot product to be fed directly into the automatic bottle filler.

Step 2: Automated Bottle Infeed & Conveyor Handling

Simultaneously, the packaging line starts automated operation, and empty glass or PET bottles are loaded onto the Rotary Loading Table. This essential piece of infeed equipment creates a buffer and manages the flow supply of bottles is fed onto the main conveyor system leading to the filling station.

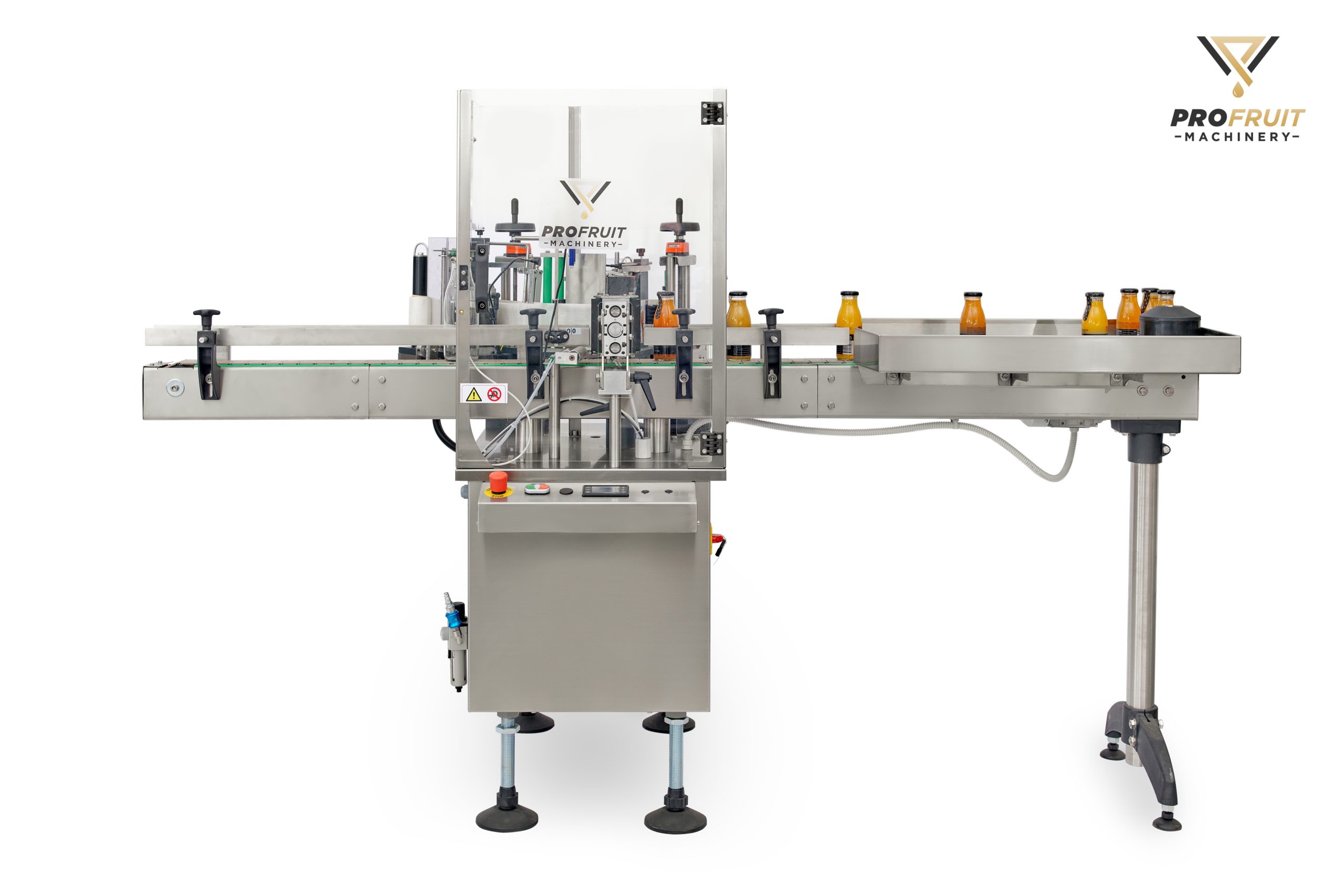

Step 3: Integrated Rinsing, Filling, and Capping with the ProFruit Triblock

The core of the beverage filling line is the ProFruit Triblock System – compact and efficient monoblock machine integrates three key operations:

- Rinsing where each bottle is thoroughly cleaned with sterile water or air.

- Filling where automatic bottle filler station receives hot, pasteurized product directly from the pasteurizer.

- Capping where integrated capping machine applies and secures twist-off caps to seal.

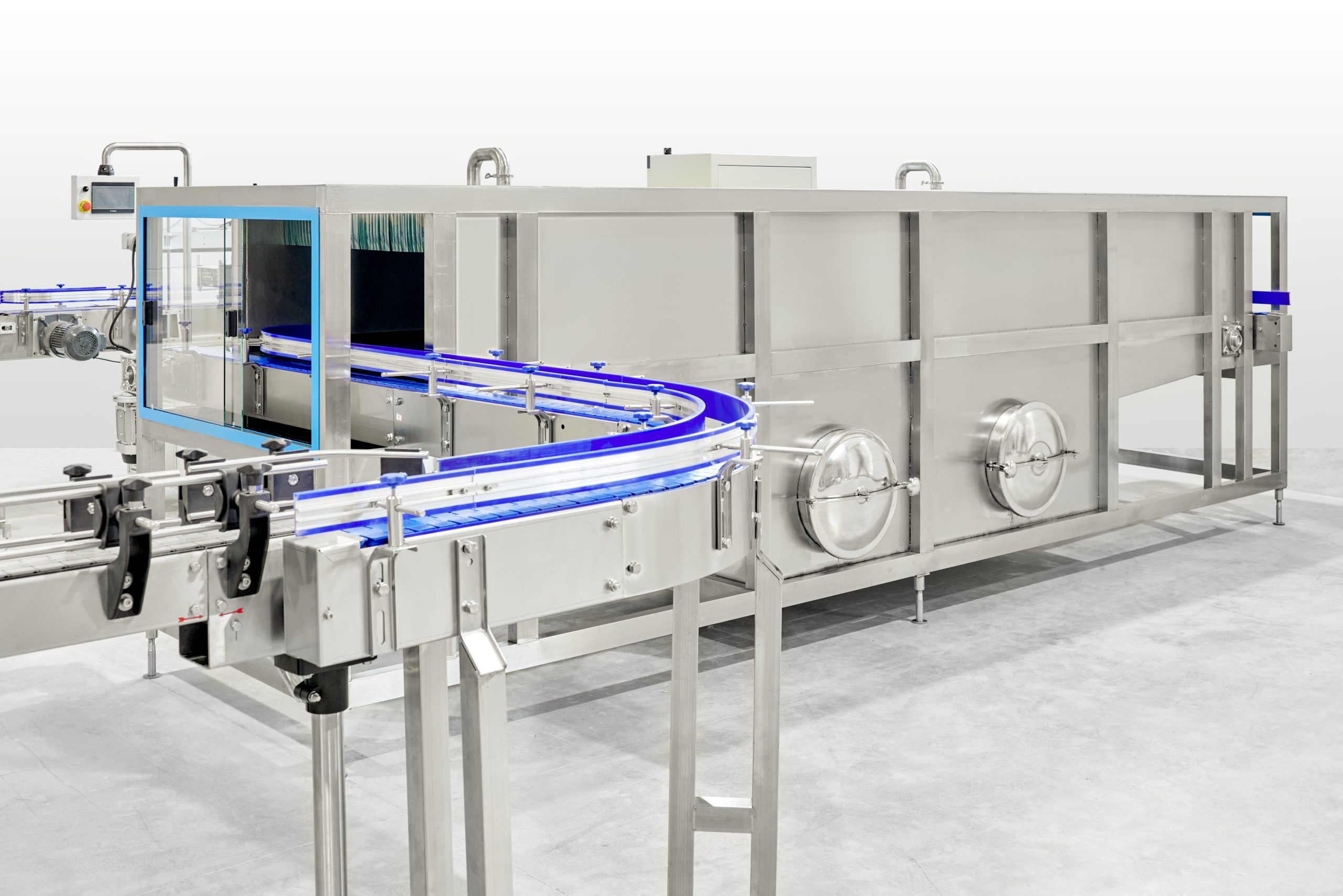

Step 4: Post-Fill Cooling in an Industrial Cooling Tunnel

After being hot-filled and sealed, the bottles immediately enter the Industrial Cooling Tunnel and controlled water spray to safely lower the product’s temperature. This post-fill cooling is vital to preserve the beverage’s natural taste and color, prevent thermal shock to glass containers, and rinse the exterior for a clean finish.

Step 5: High-Performance Bottle Drying with an Air Knife System

First bottles pass through the High-Efficiency Air Knife Bottle Dryer. This industrial drying system uses a targeted, high-velocity blast of air to shear away all moisture from the bottle’s surface and crevices, ensuring adhesion for labels and clear printing.

Step 6: Precision Labeling, Coding, and Capsule Application

This versatile self-adhesive labeling machine accurately applies front and back labels to round or shaped containers. The system can be fully integrated with an inkjet printer for batch coding and an automatic capsule applicator to place decorative PVC or aluminum capsules over the cap for a premium look.

Step 7: End-of-Line Shrink Wrapping and Multipack Bundling

The Automatic Bottle Shrink Wrapping Machine receives the finished bottles, groups them into desired configurations (e.g., 6-packs, 12-packs), and wraps them in a sleeve of film. The bundle then passes through the integrated heat tunnel, which shrinks the film tightly to create a secure, durable, and professional multipack ready for palletizing and distribution.

We always consider your preferences and tailor our line to meet your needs and desired performance level. Feel free to reach out, and we will discuss your requirements individually.

Automatic Triblock rinsing-filling-capping system

Automatic capping machine

Automatic Capping Machine

Cooling tunnel

Cooling Tunnel

Air knife bottle dryer

Air Knife Bottle Dryer

Automatic bottle labeller

Automatic Bottle Labeler

Automatic bottle shrink wrapping machine & multipack bundler

Automatic Bottle Shrink Wrapping Machine & Multipack Bundler

Why Choose ProFruit?

- Purpose-built automatic bottling machinery designed by industry veterans

- Customizable systems for both large and small-scale producers

- High-performance Rinsing, Filling, and Capping

- Real-time expert support and end-to-end operational guidance

Looking for a complete fruit processing solution with Bag in Box filling? Explore our Pome Fruit Juice Processing Line – efficient, reliable, and ready to meet your production needs.