From Harvest to Bottle – Smart, Scalable Cider Equipment

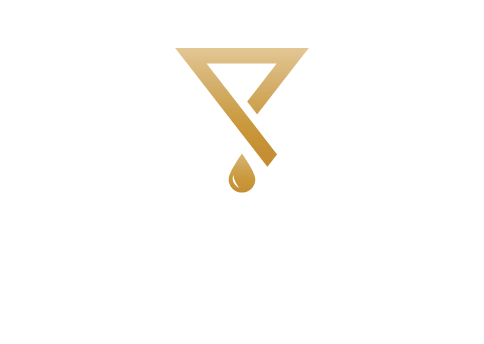

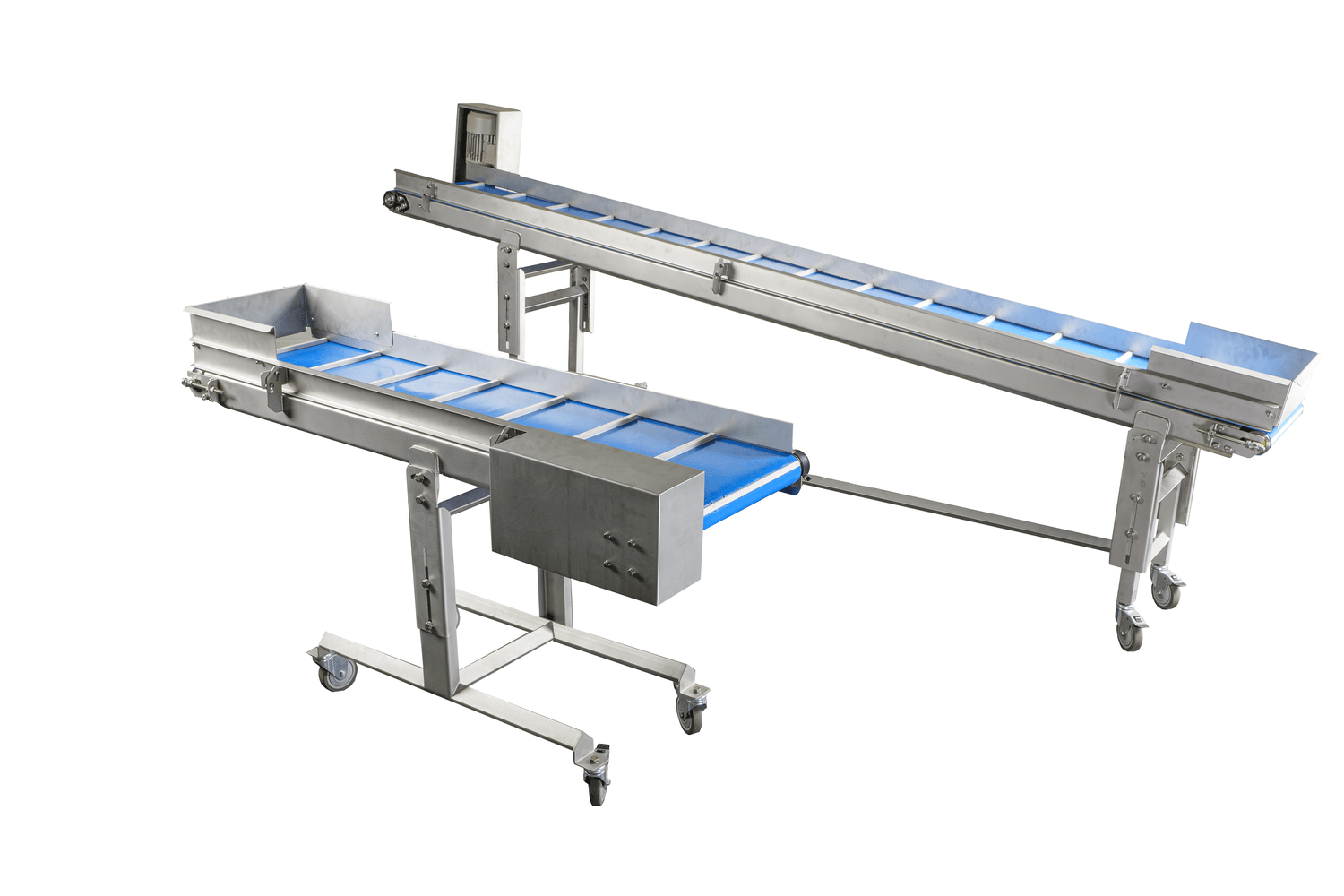

Our system begins with ergonomic handling solutions like the Bin Tipper UNLOADER 800, followed by sorting and cleaning to ensure only top-grade apples move forward. Cleanliness is essential for flavor integrity, which is why our Fruit and Vegetable Washer AQUA 3000 and integrated washer-mill combos like the AQUAMILL prepare produce with care.

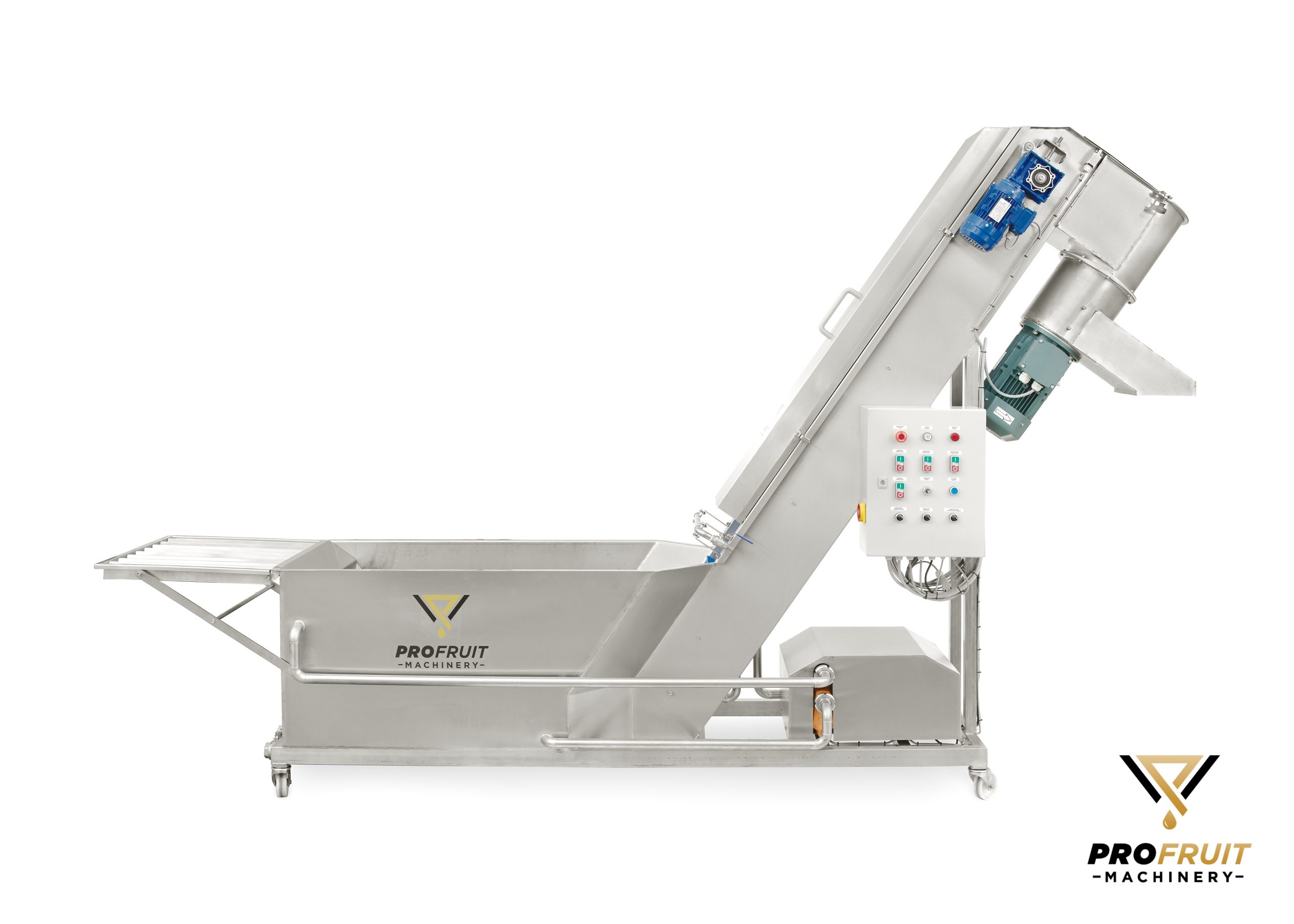

For juice extraction, our belt press systems stand out. Designed for durability and high throughput, these presses are vital cider machines. As part of your cider production machinery lineup, they extract juice efficiently while preserving natural sugars and aromas.

Fermentation takes place in specially engineered tanks – floating cover and pressure options available – each with optional cooling jackets for optimal temperature control. Once fermentation is complete, the product can be transferred to bottling using either manual or counter-pressure systems depending on the desired style.

Fermentation, Filtration, and Final Touches

No cider is complete without clarity and finish. Our cider equipment includes plate filters that deliver professional-grade clarity with minimal manual intervention. After filtration, you can choose from various bottling, capping, and labeling systems tailored for both artisanal and commercial-scale production.

Why Choose ProFruit?

- Purpose-built cider production machinery designed by industry veterans

- Customizable systems for both large and small-scale producers

- High-performance cider press, fermenters, cider pasteurizer, and bottling tools

- Real-time expert support and end-to-end operational guidance

Whether you’re scaling up or starting fresh, our apple cider production solutions are built to grow with your goals – featuring essential tools like a fruit processing machine, fruit washing machine, and fruit crusher machine to streamline every stage from raw fruit to finished cider.