Complete Line for Juice and Purée Production

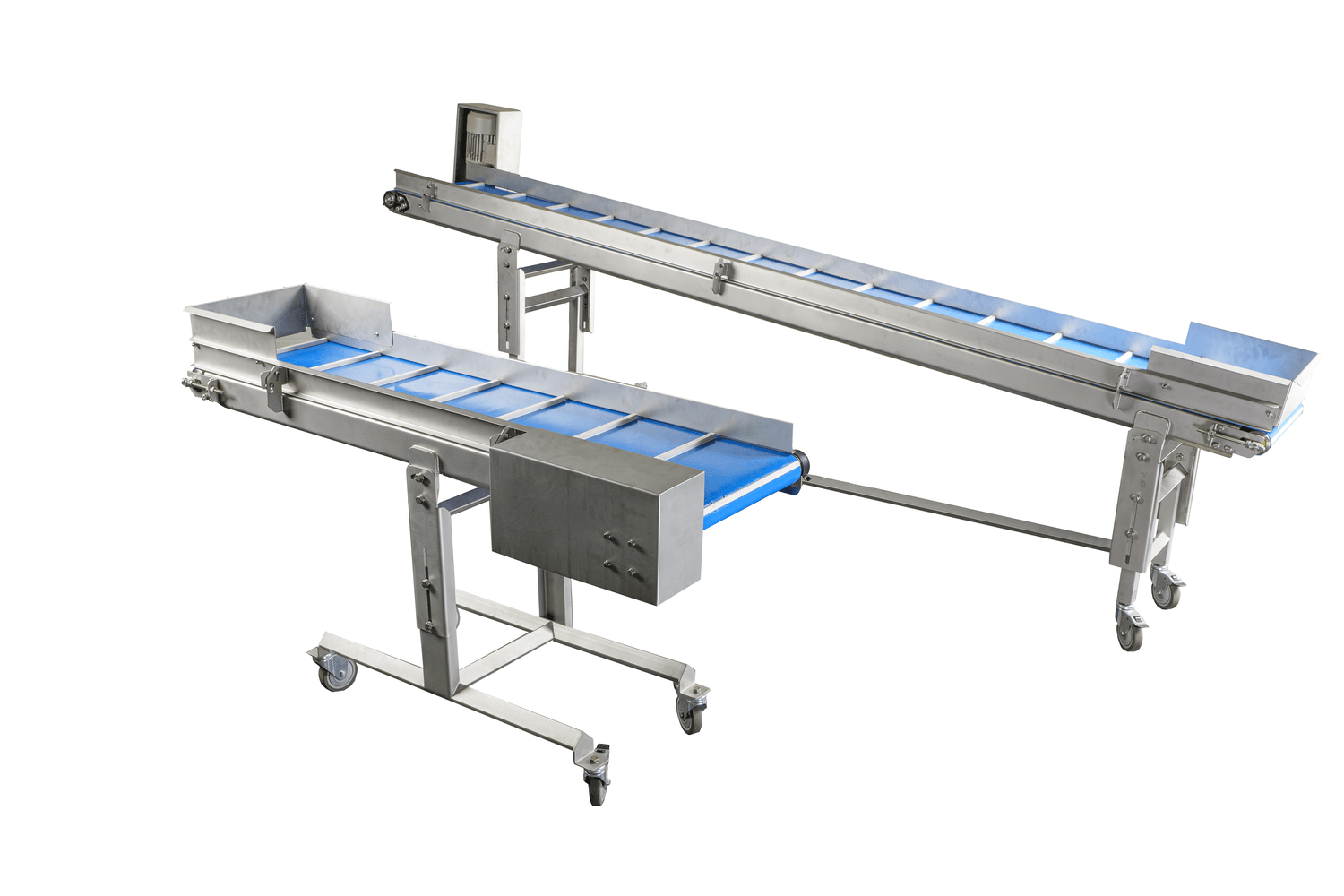

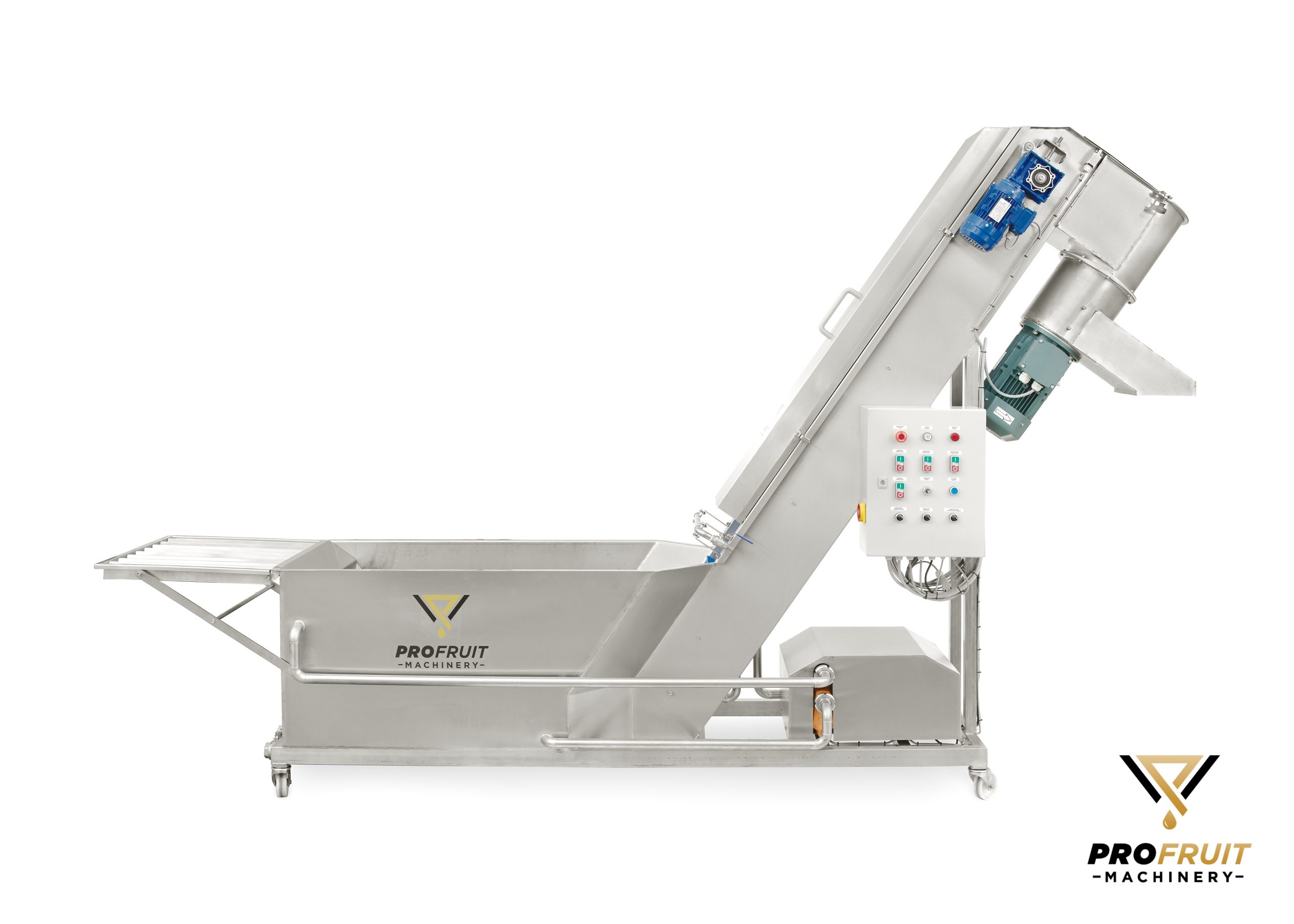

The process begins with ergonomic unloading using the Bin Tipper UNLOADER 800, followed by accurate sorting on the Sorting Conveyor. Once selected, the fruit is washed using the Fruit and Vegetable Washer AQUA 3000 – a gentle yet effective fruit washing machine that protects the integrity of delicate fruits.

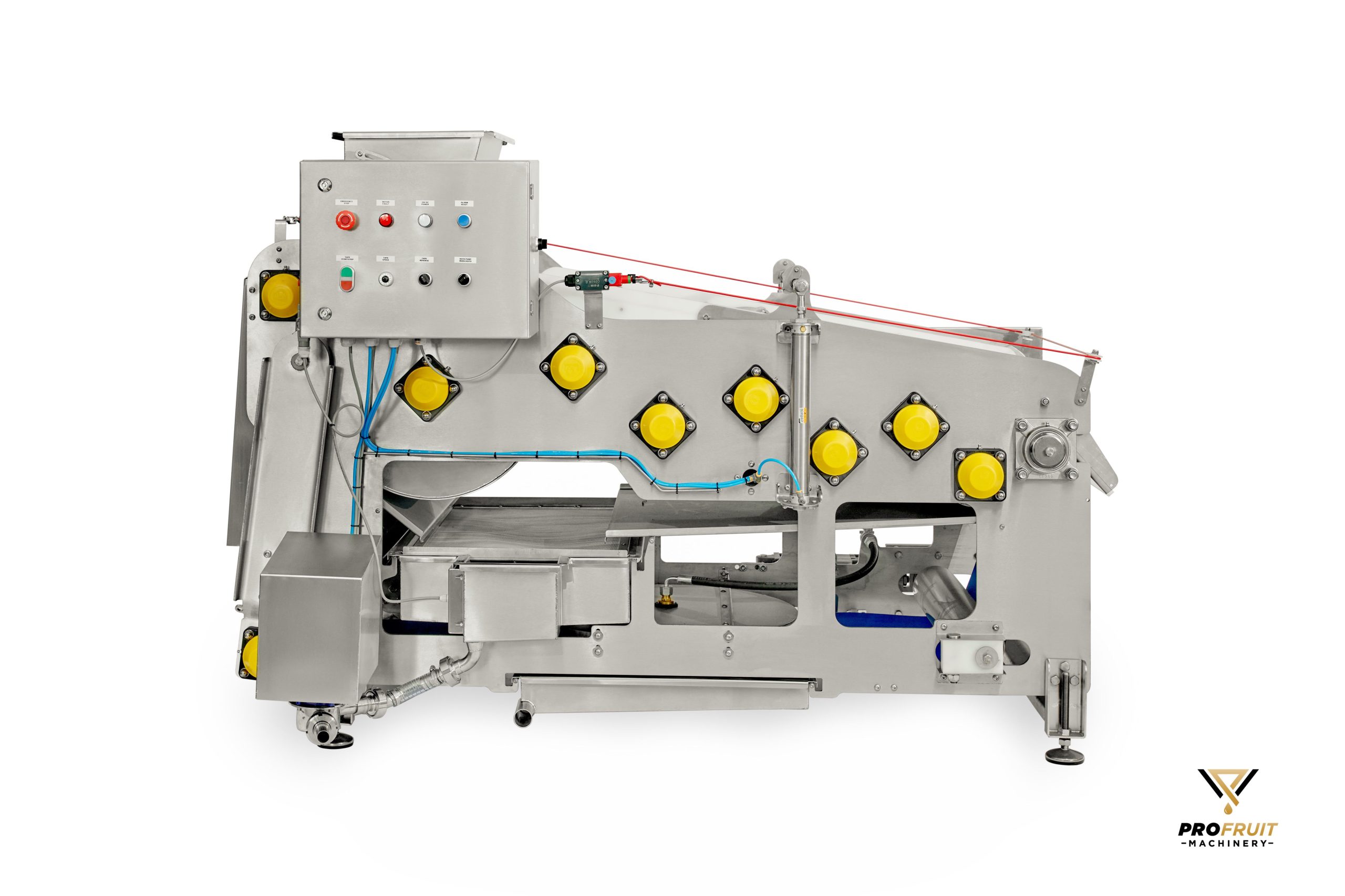

From there, the Fruit Bubble Washer Elevator Mill AQUAMILL or MAXIMILL systems carry out washing and milling in one streamlined step, converting whole fruit into mash. This mash is then transferred to our high-efficiency belt press, which ensures maximum juice yield with minimal waste.

Smooth Integration with Downstream Equipment

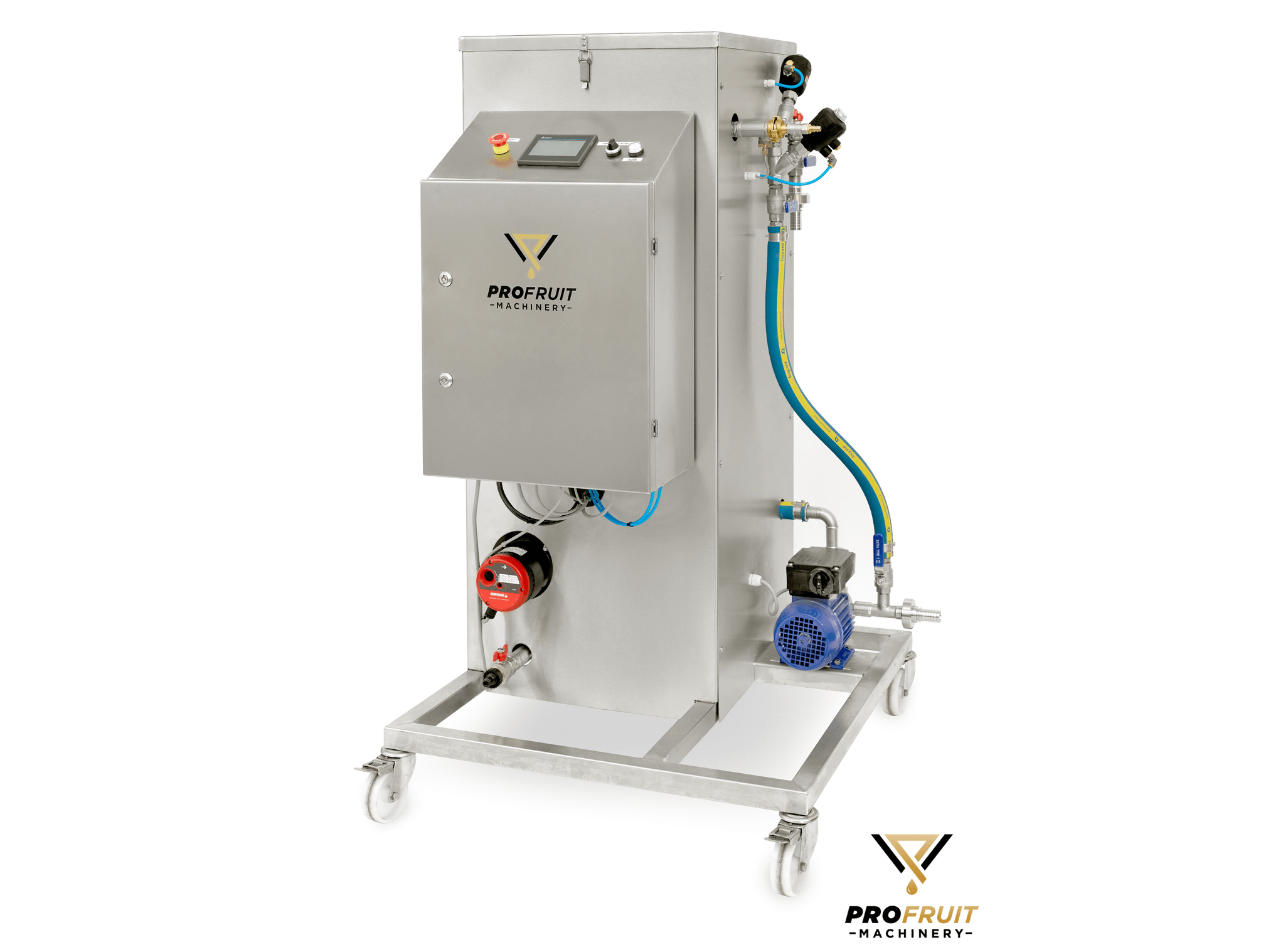

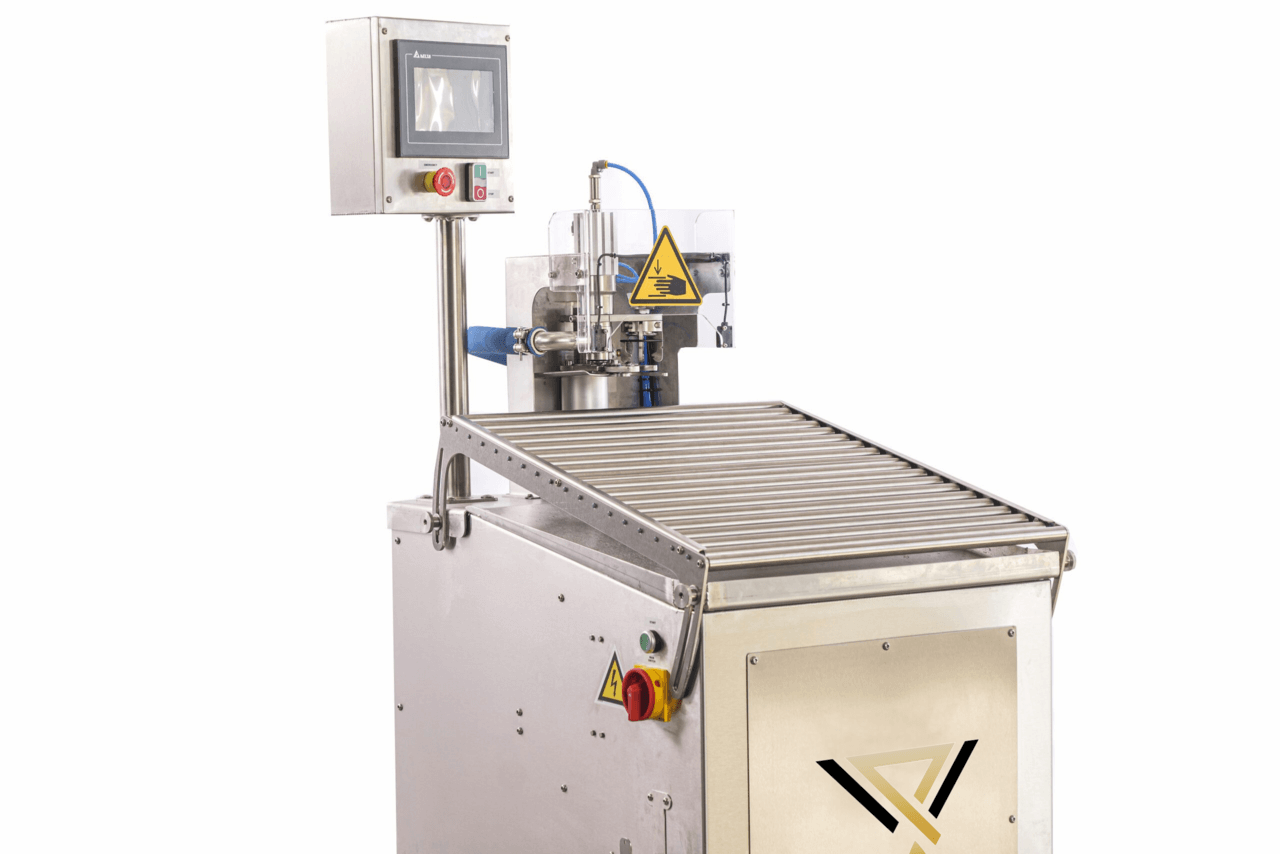

Juice homogenization and pasteurization come next, ensuring product safety and extended shelf life. Our juice pasteurizer systems – available in electric and diesel/gas models – are perfectly suited for pome fruit processing. Once pasteurized, the juice can be filled into Bag in Box, Stand up Pouch, or bottles using ProFruit’s fully and semi-automatic filling systems.

All machines are constructed from food-grade materials and designed for quick cleaning and low maintenance, making them ideal additions to any fruit processing machine line.

Why Choose ProFruit?

- Tailored for apples, pears, quince, and similar fruits

- Seamless integration from fruit washing machine to Bag in Box filler (usually with a AUTOFLOW)

- Hygienic, easy-to-maintain stainless steel construction

- Full line automation for efficient juice and purée production

ProFruit’s pome fruit processing solutions deliver reliability, efficiency, and top-quality results at every stage.