From Raw Fruit to Final Product

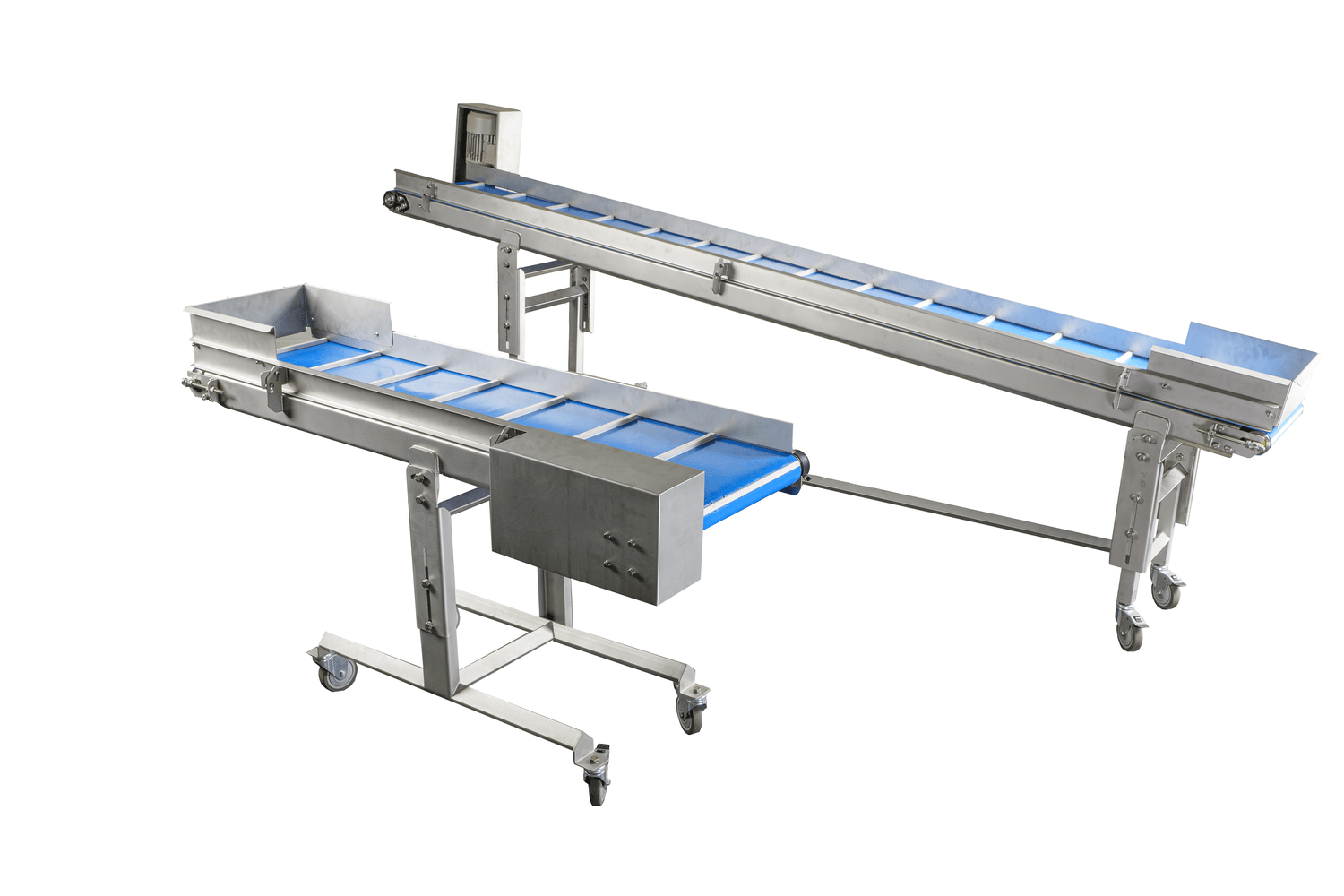

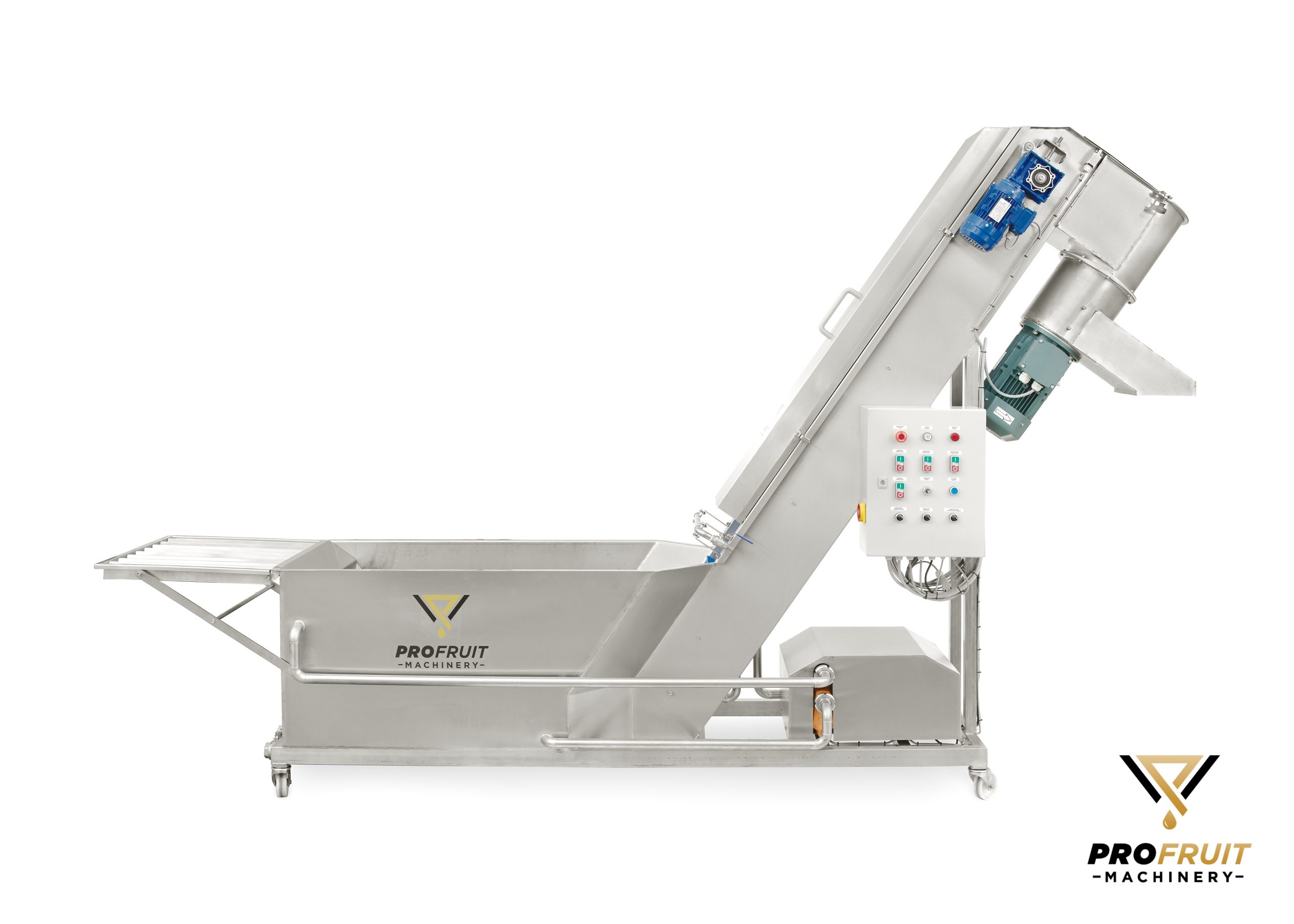

The process starts with the Bin Tipper UNLOADER 800, allowing for smooth unloading and transfer of raw produce. From there, Sorting Conveyor conveniently transports products. It ensures easy and smooth sorting of fruits. The Fruit and Vegetable Washer Elevator Mill MAXIMILL or AQUAMILL follows, washing and milling the fruit into a mash suitable for further treatment.

If the mash is destined for fermentation, a single-stage destoning and pulping machine is enough. For nectar or purée production, the second pulping stage delivers a refined, smooth texture. All this is handled by robust fruit processing machines that are engineered for reliability and food-safe operation.

Storage, Homogenization & Pasteurization

Once processed, the mash or nectar can be stored in stainless steel tanks, including models with integrated mixers for optimal product uniformity. The juice homogenizer ensures consistent texture and taste, vital for premium stone fruit beverages.

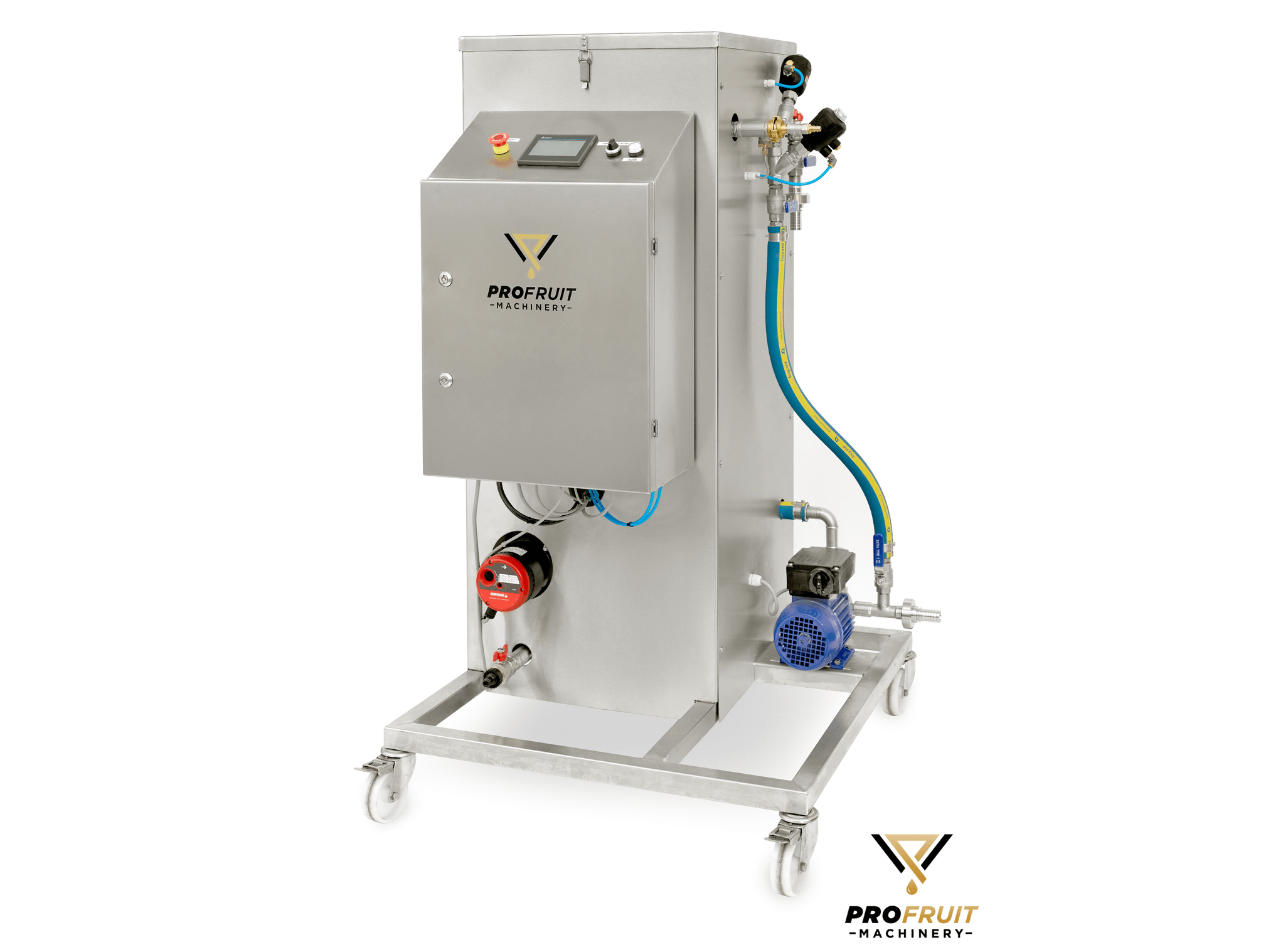

To secure product safety and shelf life, ProFruit offers both electric and gas/diesel juice pasteurizers, capable of hot-filling and compatible with a wide range of fruit products.

Smart, Versatile Packaging

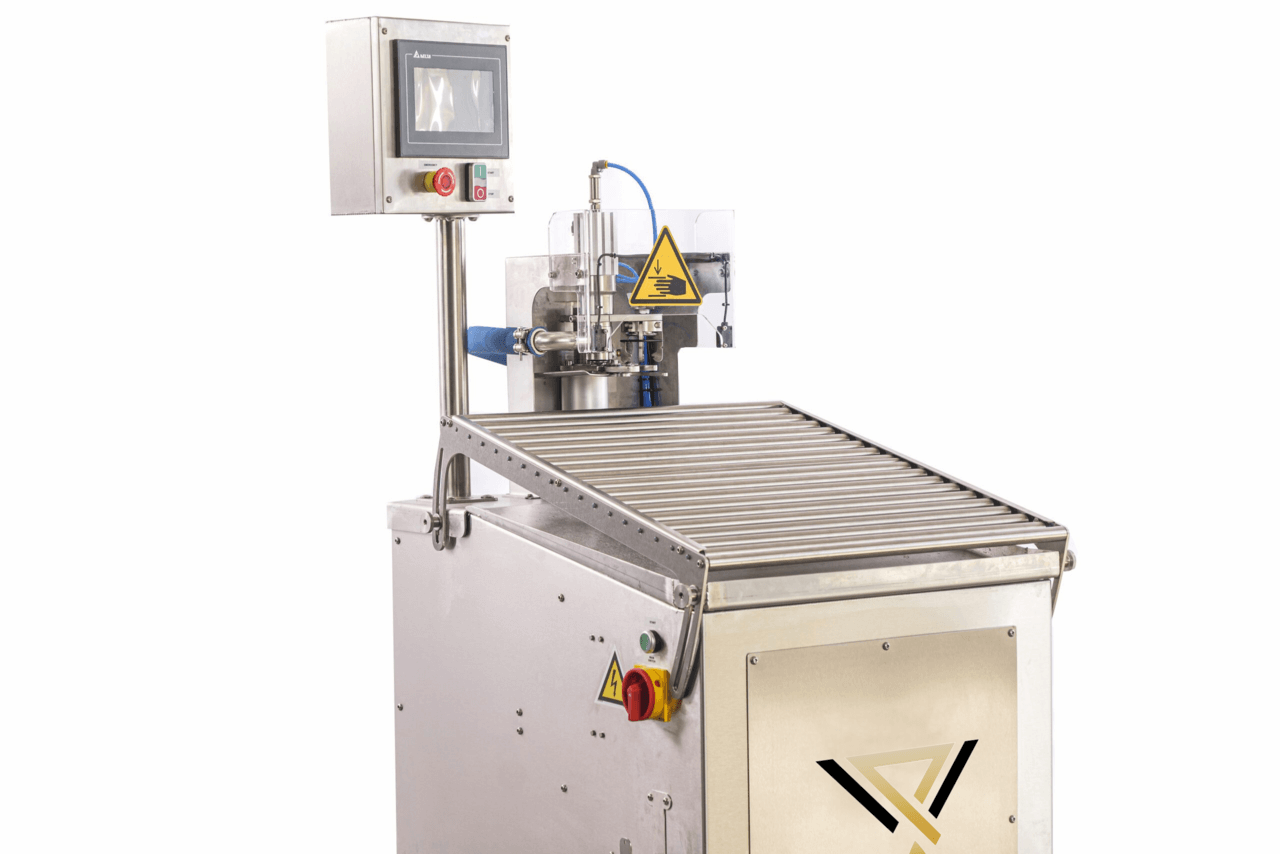

The final step is seamless packaging using the Automatic Bag in Box Filler AUTOFLOW, Stand up Pouch fillers, or bottle filling and capping monoblocks, providing flexibility for different market needs.With ProFruit’s stone fruit processing line, you’re investing in a complete, scalable solution that includes every high-quality fruit processing machine you need for premium juice, purée, or fermentation production.