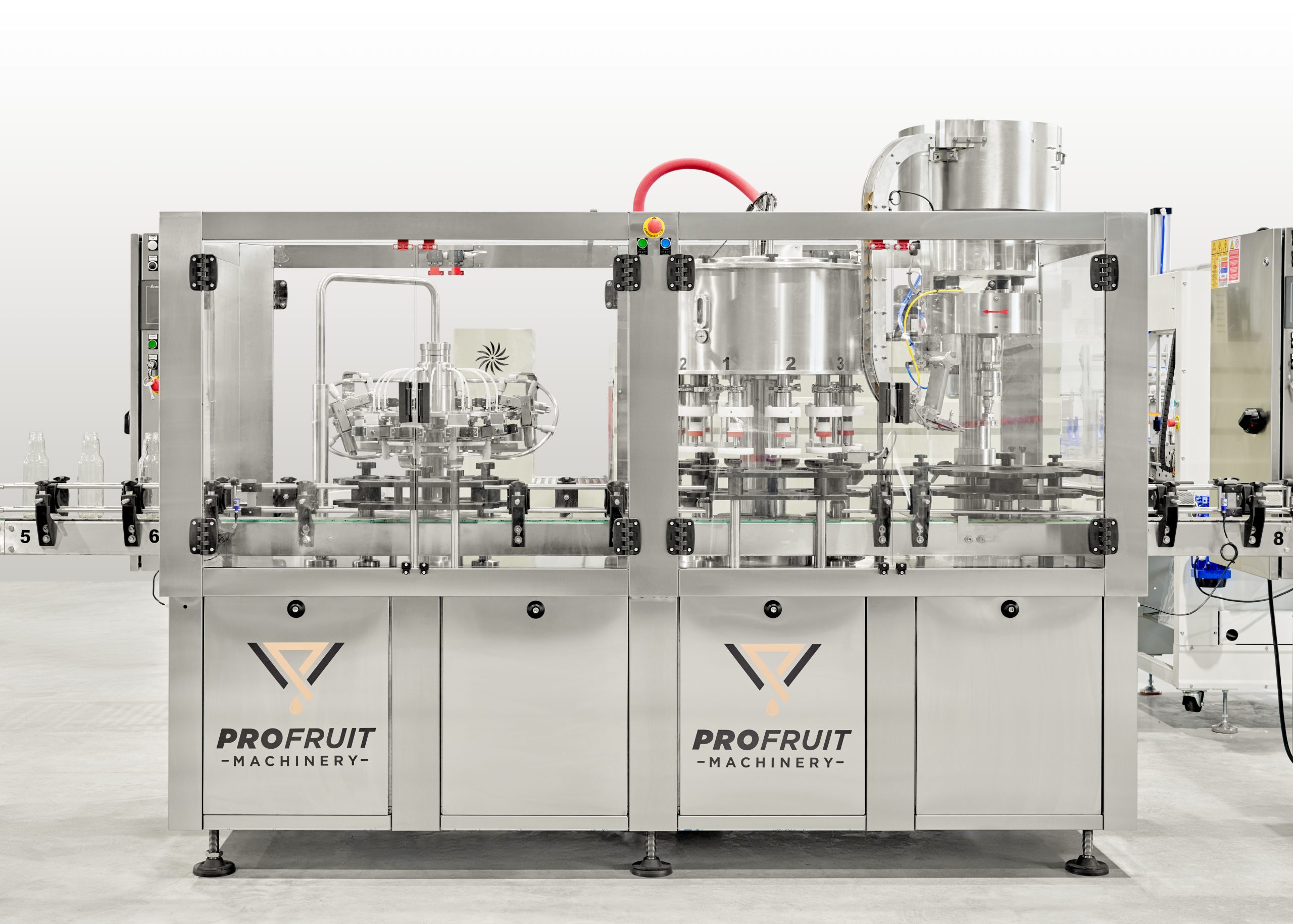

ProFruit Machinery offers flexible 8–12 head model with an integrated rinsing, filling, and capping machines. Our triblock systems ensure smooth and hygienic transition from empty bottle to finished product.

Capacity – 500-2,500 BPH.

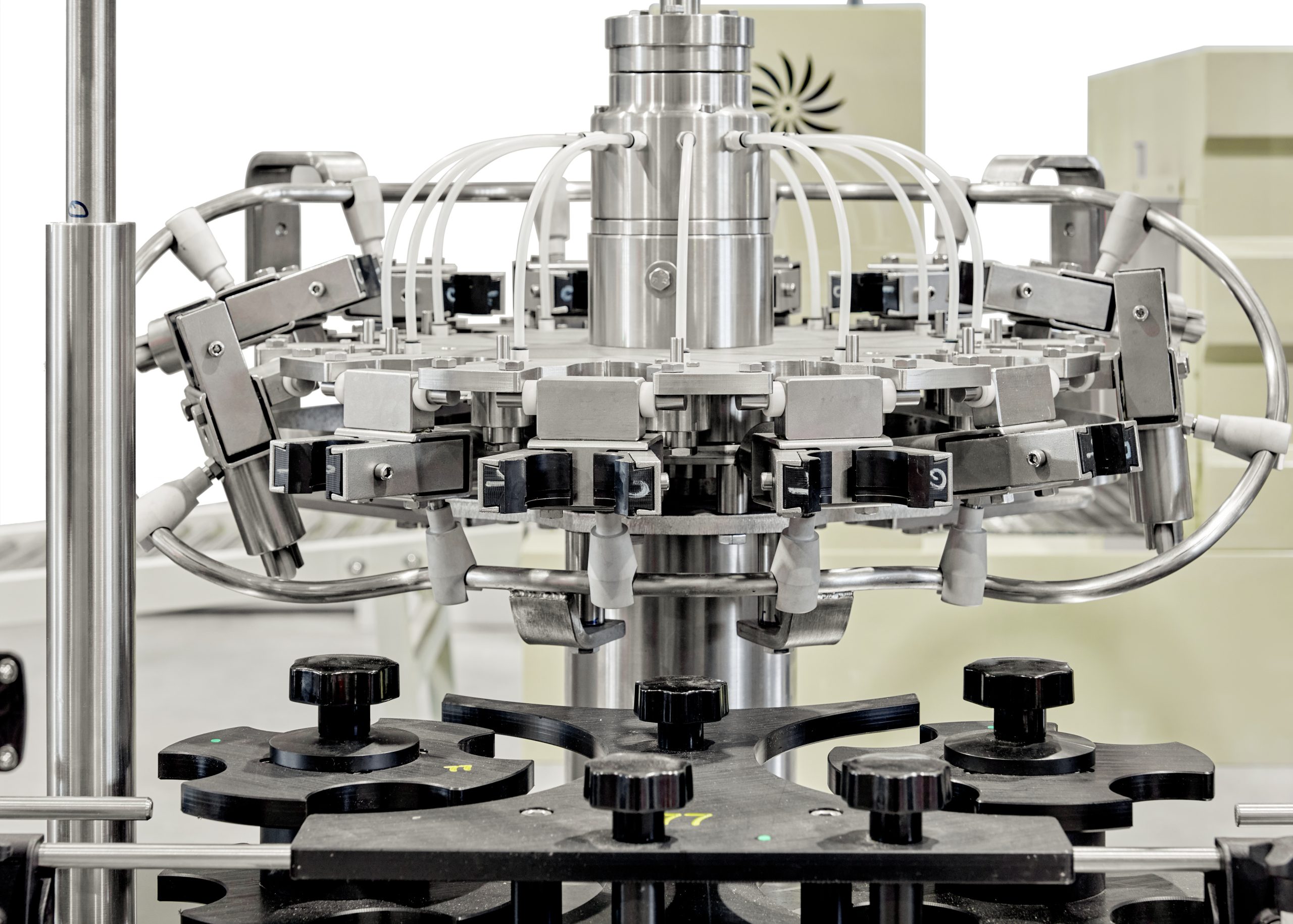

- Automatic bottle rinser.

- High-precision bottle filling.

- Versatile capping solutions.

The finished product exits to further processing steps such as labeling and case packing. ProFruit triblock systems integrate multiple functions into a single unit, streamlining production workflow.

- Adjustable speeds from 500-2,500 BPH that meets your productivity goals.

- A unified control system prevents timing issues of separate machines, minimizing spillage and maximizing uptime.

- The enclosed, easy-to-clean design minimizes contamination risk and ideal for food and beverage use.

- A central touch-screen lets one operator manage startup, speed, and format changes.

- Our machines offer flexible height adjustment and optional parts for various glass and PET bottle shapes and sizes.

Enhance your bottling line with a wide range of optional triblock customizations to meet your specific needs.

- Modify your system for hot-filling juices, teas, and other beverages that require pasteurization.

- Equip your triblock with specialized components for handling and filling various lightweight PET bottles.

- A nitrogen injection unit can be added before or after filling to displace oxygen, preserving freshness, color, flavor and extend shelf life.

- Add a fully automated washing system with dummy bottles for efficient cleaning in place cycles.

- Order extra tooling sets (starwheels, guides) to quickly switch between bottle shapes and sizes.

- Advanced Automation & Sensors:

- If a cap is missing machine stops to prevent unsealed products.

- Detects bottle backups by bottle jam photocell at the outlet and stops the machine to prevent damage.

- Supplementary equipment

- Integrate the right pump for your product’s viscosity and flow needs.

- Reduce water use with a closed-loop rinser system featuring a filter and pump.

- Continuously feed caps to the capper using a hopper and automated elevator.

- Create a buffer and automate empty bottle infeed with a rotary table.

Looking for a compact monoblock solution? Discover our Bottle Filling and Capping Monoblock – an all-in-one system for efficient and seamless bottling.