Our advanced heat pump technology provides a gentle, efficient, and highly controllable drying environment, perfect for producing premium-quality dried fruits, vegetables, herbs, and more. By using a closed-loop system to recycle heat, the DRYFRUIT dryer significantly reduces energy consumption while preserving the natural color, aroma, and vital nutrients of your products.

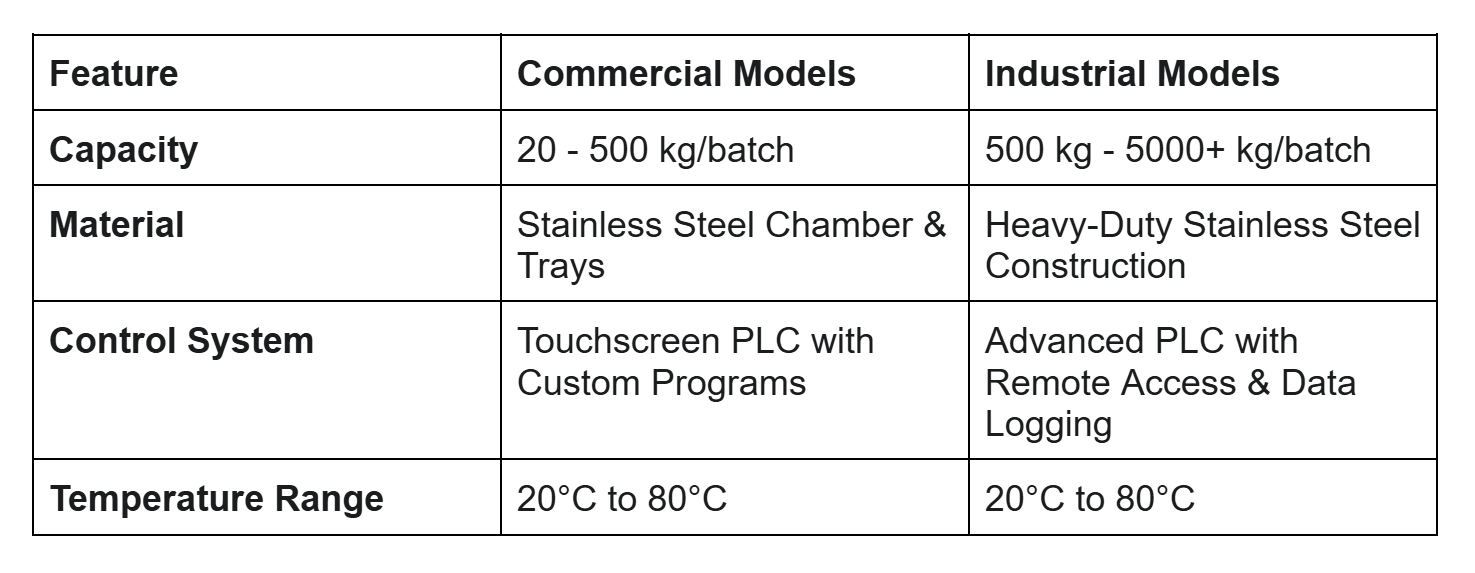

We offer a complete range of DRYFRUIT models, from commercial-scale units for small businesses to large, industrial-scale heat pump dryers designed for high-volume production.

Key Benefits:

- Superior Quality Preservation – low and medium-temperature drying (20-80°C) is gentle on your products, preventing case hardening and minimizing the loss of vitamins, color, and flavor.

- Massive Energy Savings – our closed-loop heat pump system recycles and reuses energy from the drying process, consuming up to 75% less electricity than conventional electric dryers, leading to significant operational cost savings.

- Hygienic and Contaminant-Free – the sealed drying chamber protects your product from external dust, insects, and contaminants, ensuring a clean and sanitary final product.

- Precise Control – smart user-friendly touchscreen PLC system allows for precise control over temperature and humidity.

- Versatile & Multi-Purpose – is ideal for a wide range of products: drying fruits (apples, mangoes, berries), vegetables, herbs, spices, meat, and more.

- Environmentally Friendly – no waste heat or emissions are released into the atmosphere, making them an eco-friendly choice.

The work process:

The DRYFRUIT operates like a dehumidifier in a closed, insulated chamber.

- Evaporation – the heat pump generates warm, dry air that is circulated over the product on trays, causing moisture to evaporate.

- Dehumidification – the moist air is then drawn back through the heat pump’s evaporator, where it is cooled, causing the water to condense and drain away.

- Heat Recovery – the energy captured during the condensation process is recycled to heat the now-dry air, which is then sent back into the chamber to continue the cycle.