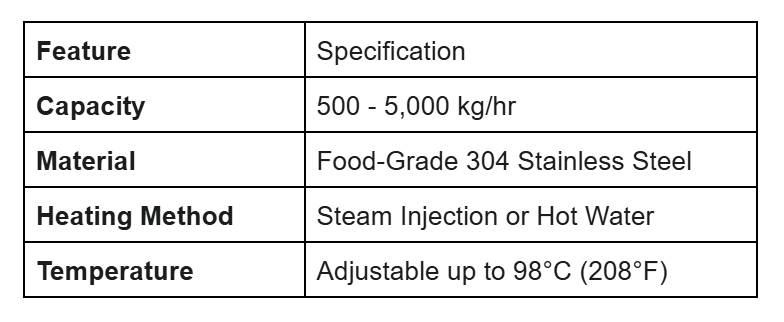

This automated system is essential for preparing produce for juicing, freezing, drying, or canning. It also serves as a key sanitation step before juicing by reducing the surface microbial load.

Key Features & Benefits:

- Improves Safety for Juicing – significantly lowers the bacterial count on raw produce, a crucial pre-treatment step for creating safer, more stable cold-pressed juices with a longer shelf life.

- Softens Peels for Easier Processing – the heat treatment softens the tough skin of fruits like mangoes, peaches, and tomatoes, making them significantly easier to peel manually or mechanically.

- Preserves Quality – inactivates enzymes to lock in the natural color, flavor, and texture of fruits and vegetables.

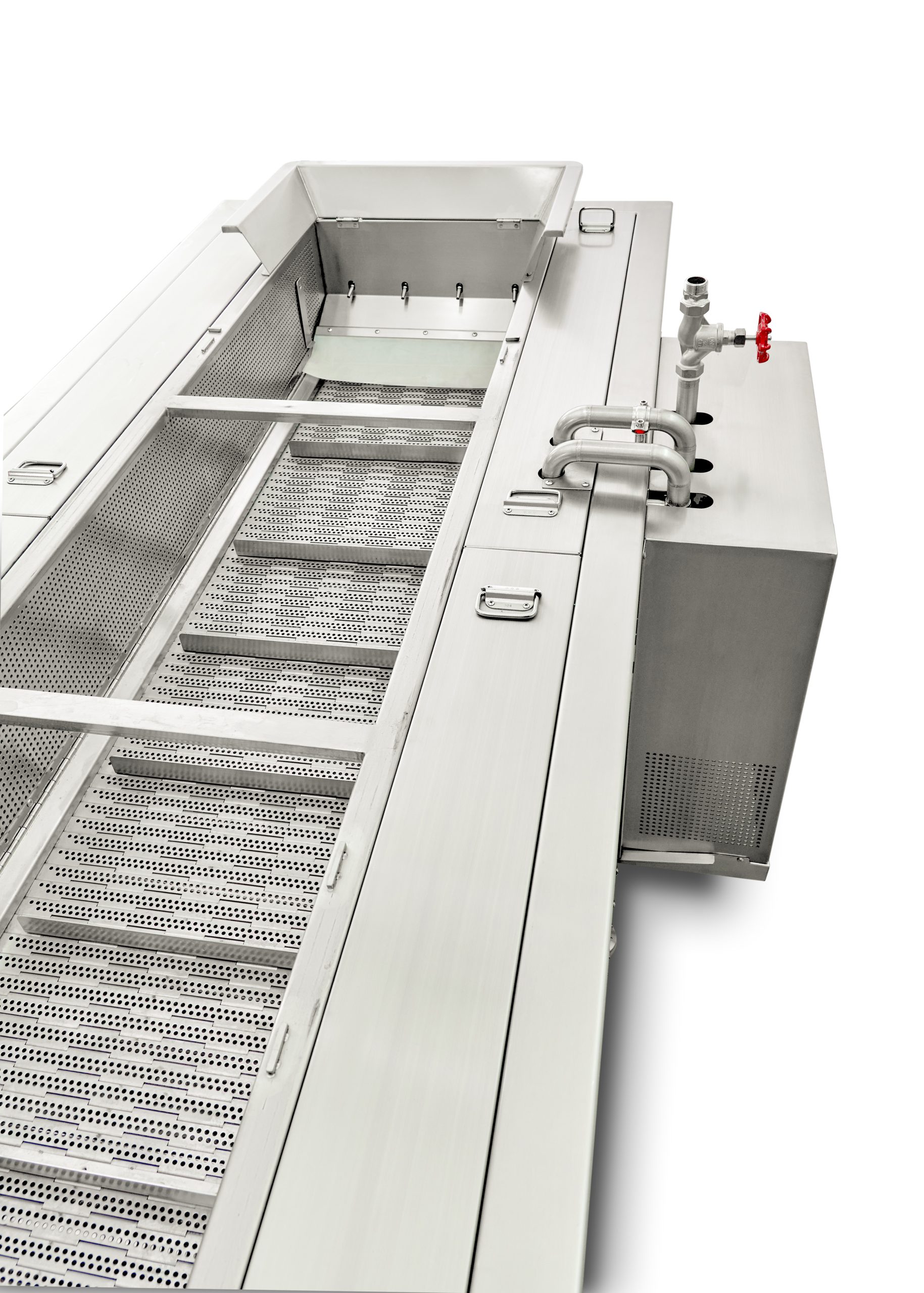

- High-Efficiency Throughput – a continuous conveyor belt seamlessly processes large volumes, eliminating batching and increasing output.

- Precise Control – fully adjustable temperature and belt speed allow for perfect, uniform consistent blanching results every time.

- Hygienic Design – constructed entirely from food-grade 304 stainless steel for durability and easy cleaning.