The mobility of the processing line has allowed our business to grow rapidly. We can now press juice directly at different locations, saving on facility costs while maintaining excellent efficiency. The machinery performs exceptionally, enabling us to serve more customers during the busy season.

The Benefits

The Mobile Fruit Processing Line has transformed Mana Sula’s operations by delivering:

- High Capacity: Processing up to 1200 kg of fruit per hour to meet customer demand.

- Mobility: Operating at various locations, reducing fixed costs.

- Efficiency: Automated processes deliver 75% juice yield with minimal waste.

- Ease of Use: Requiring only one person to manage the entire line.

- Versatility: Packaging options include both Bag-in-Box and Stand-up Pouches.

This solution has enabled Mana Sula to expand sustainably while maintaining the quality they’re known for.

1

efficiency

1

person for operating

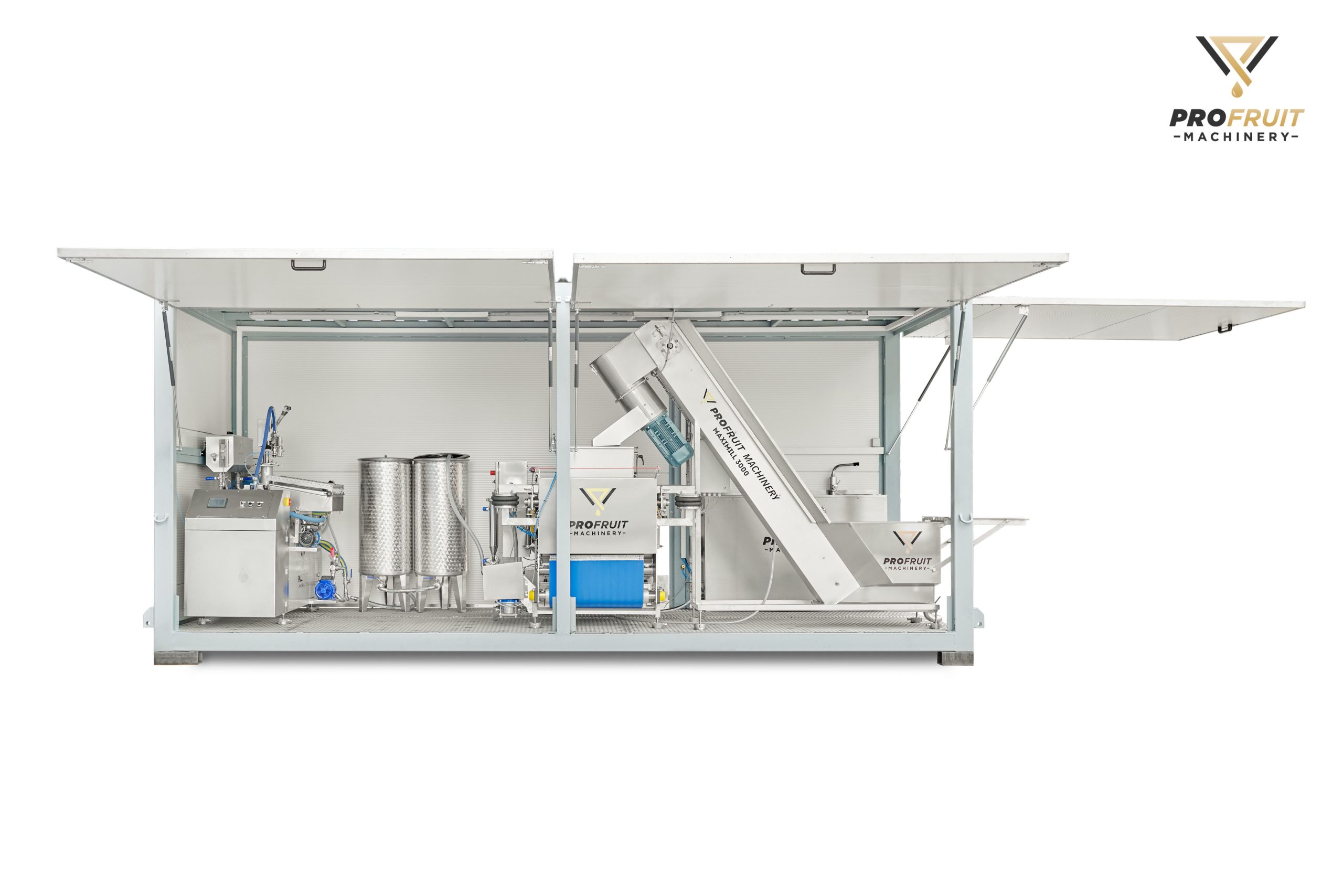

The Client Bought

You can check out the machinery which our client ordered and inspect the details by clicking on any of the products below.

Juice Pressing

Mobile Fruit Processing Line contains all machines for juice production and offers a possibility to process various fruits and produce juice at your selected place.

Other Projects

Read the case study articles about our other projects where we customized our fruit processing and filling machinery and provided it to our clients from all over the world.

Glenbourne Cider – Canada

Glenbourne, a family-run cidery in Nova Scotia’s Glen Tosh valley, grows over 4,000 apple trees with a focus on quality, community, and sustainability. To achieve their goal of producing premium cider and juice, they invested in our 800 kg/h apple processing line, later upgrading to a 3,000 kg/h system to support future growth and fruit expansion.

Yablena Natura – Bulgaria

Yablena Natura focuses on producing organic apples, pears, and sour cherries in over 2,000 decares of orchards located 80 km from Sofia at 700 meters altitude, in the villages of Radotina, Kraevo, and Novachene at the foot of the Stara Planina Mountains.

Engin Tarim – Turkey

Engin Tarım cultivates 12 000 decares of apple orchards and 3 500 decares of avocados, producing 55 000 tons of high-quality apples every year. They chose ProFruit for their expantion into apple juice production.

Martin Family Orchard – USA

Martin Family Orchards, a family-run farm from Wenatchee, Washington—the apple capital of the world—recently expanded from fresh fruit growing into cider production using their own apples.